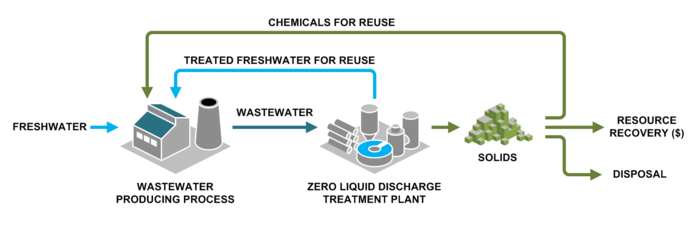

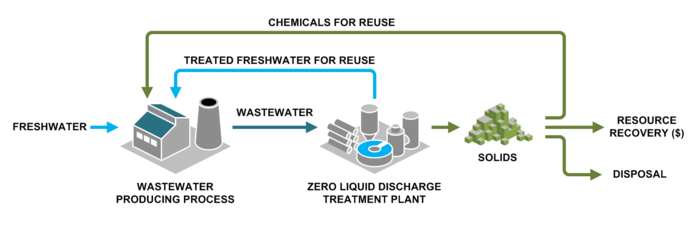

Zero liquid discharge is a process that is beneficial to industrial and municipal organizations as well as the environment because it saves money and no effluent, or discharge, is left over. ZLD systems employ the most advanced wastewater treatment technologies to purify and recycle virtually all of the wastewater produced.

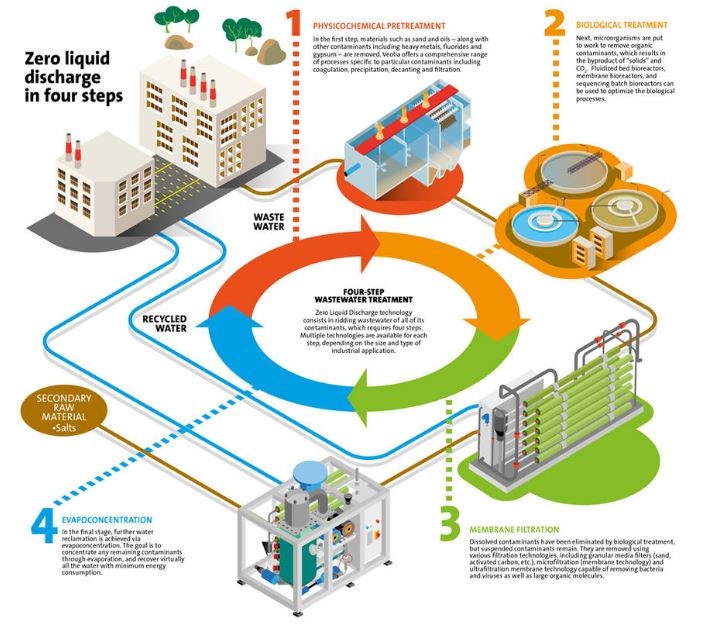

A zero liquid discharge process diagram that highlights how wastewater from an industrial process is converted via a ZLD plant to solids and treated water for reuse.

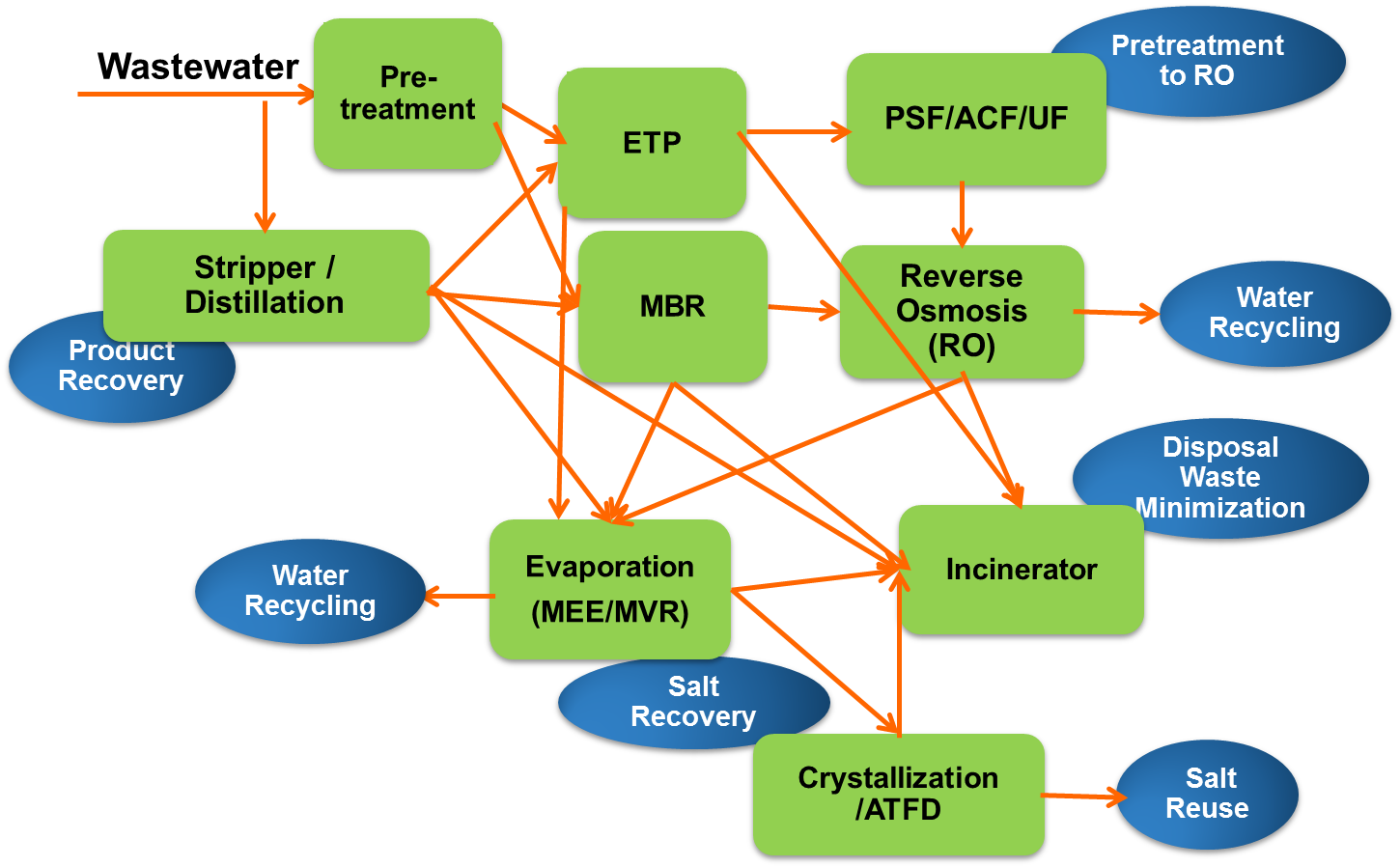

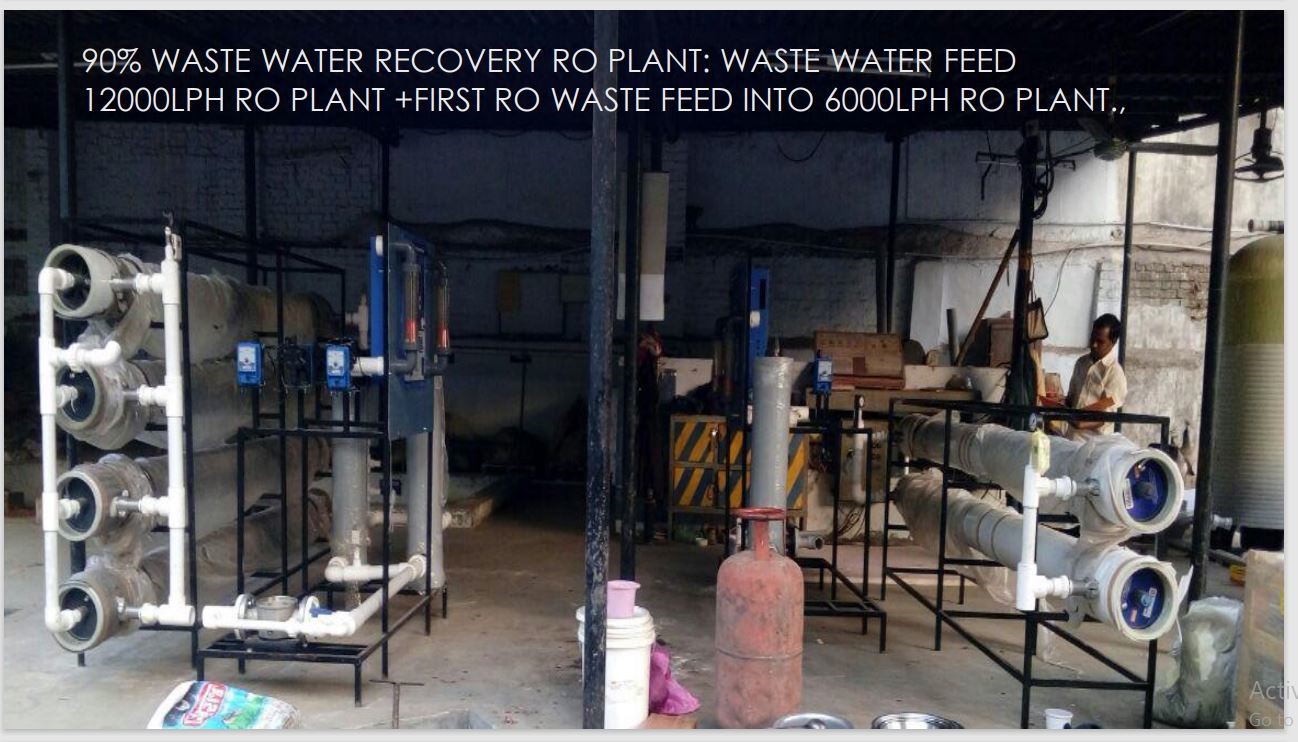

By Using Integration of Technologies, We Can Get 85-95% Recovery And Remaining 5%-15% Will Go To MEE For Evaporation. Which Means There Will Be Zero Liquid Discharge. Aquila Provides ZLD Systems Based on Water Characteristics and As Per Your Requirement.

We Offer Quality Range of Zero Liquid Discharge Plants Which Are Widely Used in Industries. By Using Various Technologies, We Provide Absolute Solution.

A zero liquid discharge process diagram that highlights how wastewater from an industrial process is converted via a ZLD plant to solids and treated water for reuse.

Zero liquid discharge is a process that is beneficial to industrial and municipal organizations as well as the environment because it saves money and no effluent, or discharge, is left over. ZLD systems employ the most advanced wastewater treatment technologies to purify and recycle virtually all of the wastewater produced. Also Zero liquid discharge technologies help plants meet discharge and water reuse requirements, enabling businesses to:

• Meet stringent cooling tower blowdown and flue gas desulfurization (FGD) discharge regulations.

• Treat and recover valuable products from waste streams.

• Better manage produced water.

A Zero liquid discharge facility (ZLD), is an industrial plant without discharge of wastewaters. Target ZLD is normally reached by

• Waste water strong recovery

• Separation by evaporation or boiling of water part of waste water not reusable, in evaporators, crystallizers and condensate recovery. ZLD plants produce solid waste

• Filtration System

• COD Removal/Nano Filtration Plant

• Ultra Filtration Plant

• Reverse Osmosis Plant

• MEE System